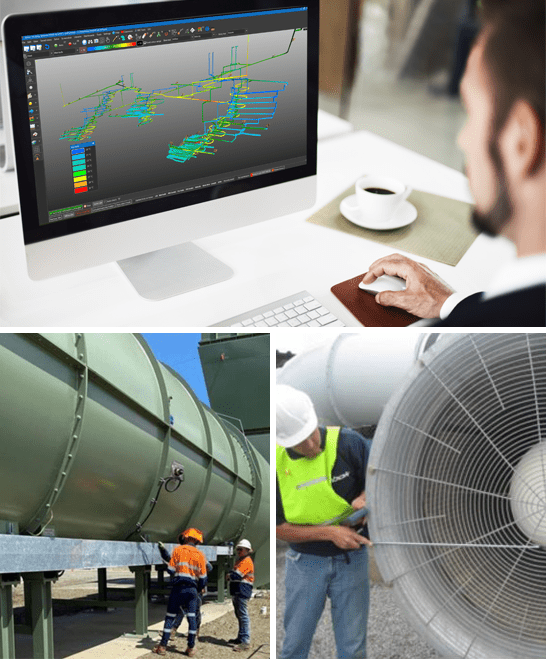

Mine Ventilation Surveys and Model Calibration

Calibrating ventilation models to reflect real-time mine conditions allows ventilation practitioners to gain precise control over air distribution and temperature predictions throughout the mine. This alignment not only ensures air reaches critical areas effectively but also enables “what-if” scenario testing, offering a risk-free way to assess the impact of adding seals, doors, fans, or other ventilation controls. By modelling these adjustments, practitioners can make data-driven decisions that enhance system performance and safety.

BBE provides comprehensive ventilation surveys and delivers calibrated ventilation models, backed by high-quality data from key locations in the mine. With BBE’s expert survey and calibration services, you can be confident that your model is up-to-date and accurately represents the current state of your ventilation system, enabling more effective planning and optimization.